a333 gr.6 impact test|astm a333 gr6 pipe : purchasers This page introduced the impact test on ASTM A333 Gr.6 seamless pipes which are widely used in coolant piping systems of nuclear power plant, sour oil & gas pipeline, and offshore plant forms: impact temperature, specimens, testing . web30 de jun. de 2022 · A Neteller é um serviço global de transações eletrônicas de dinheiro. Por meio dessa carteira digital, é possível fazer pagamentos online, saques com os cartões físico e virtual e transferência para mais de 200 países. Além disso, a empresa conta com medidas de segurança que são projetadas para manter o seu dinheiro seguro tanto .

{plog:ftitle_list}

web5 de jul. de 2022 · Boate Gruta Azul - Floresta, Porto Alegre, RS. R. Gaspar Martins, 230, 90220-160 Porto Alegre, RS. (51) 3222-9380. grutaazulclub.com.br. atualizado em .

Shell piping specs for low temp using A333 Gr 6 requires impact testing at the specified lower design temp for temps ranging from 0degC to -50degC. The minimum impact test temperature for Grade 6 by material specification is -45 deg C. Yes, you will need to impact test at temperatures below -45 deg C for use. Can this .

sterility test for eye drops

This page introduced the impact test on ASTM A333 Gr.6 seamless pipes which are widely used in coolant piping systems of nuclear power plant, sour oil & gas pipeline, and offshore plant forms: impact temperature, specimens, testing . A333 Gr 6 is commonly welded with WPSs qualified with impact testing. Given the minimum temperature listed in Table A-1 for this material, to me it would just be easier to . The A333 Gr 6 steel is designed to withstand brittle fracture and has excellent impact toughness, making it ideal for use in cold environments up to a temperature of -45°C. For applications of A333-6 pipe material below -45°C, .

ASTM A333 Grade 6 pipe is common use material for low temperature services in above -45℃, with yield strength minimum at 240 Mpa, and tensile strength 415 Mpa.

sterility testing of eye drops

The low alloy steel pipe of ASTM A333 Gr.6 with a low CDBTT can be used at temperatures down to -45°C [-50°F]. It is important to verify that the pipe materials are impact tested and exhibit a sufficient high Charpy toughness.ASTM A333 covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferritic steel are included.The A333 Gr 6 steel is designed to withstand brittle fracture and has excellent impact toughness, making it ideal for use in cold environments up to a temperature of -45°C. For applications of . The client is saying that the impact should be done at the rated temperature of the material A333 Gr 6 which is approx. -45 degrees C. Their specification doesn't mention anything about impact testing should be done at -45 degrees C. He is using the ASTM Specification A333 as his reference.

sterling rope hitch drop test

For example, the ASTM A333 Grade 1 pipe has a minimum impact test temperature of -50°C, which has good weldability and high toughness, and is commonly used in applications such as mild low-temperature pipes and equipment. The minimum impact test temperature for ASTM A333 Grade 3 tubing is -150°C. Suitable for extreme low temperature .

A333 Gr 6 is typically used in applications where temperatures can drop as low as -50°F (-45°C), and its chemical composition is designed to provide high-impact toughness at these temperatures. This specification covers . thread794-379767: A333 Gr 6, what is the minimum temperature without impact testing? To determine which curve applies to SA333-6 we have to refer to Fig. UCS-66 [Section VIII Div. 1]. Start of in Curve B since clause 2(c) states “all pipe, fittings, forgings and tubing not listed for Curves C & D below” (since SA333 Grade 6 is not .Check stock Carbon Steel A333 Seamless Pipe, ASTM A333 gr 6 Schedule 40/80 at best price. ISO 9001:2015, IS0 45001:2018 Certified company; [email protected] +91-22-23634200; Home; About; Products. Pipes; Fittings; . Other Temperatures for Impact Test: Hydrostatic Test or Nondestructive Electric Test: Test Report Required:ASTM A350 (ASME SA350) is carbon and low alloy steel flanges for low temperature services.Common use grade ASTM A350 LF2 Class 1, for temperature at -45℃. . corresponding material for piping in ASTM A333 Grade 6 and pipe fittings in ASTM A420 WPL6. With yield strength minimum 240 Mpa, and tensile strength in 480 Mpa to 655 Mpa, impact test .

While the tensile properties of this alloy are moderate, according to this specification the LTCS ASTM A333 Gr 6 Pipe is put through the following tests - hydrostatic tests, and nondestructive electric tests in addition to tensile tests & impact tests.Apart from producing A333 Grade 6 Seamless Pipe, the welded pipe must not be welded by the use of any filler metal.

ASTM A333 Grade 6 is a low temperature carbon steel pipe used in various industrial applications such as petrochemical plants, power plants, and refineries. It is characterized by its high tensile strength, . • E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

For applications of A333-6 pipe material below -45°C, there will be a requirement for impact testing. Benefits of ASTM A333 GR 6 CS Pipe. ASTM A333 GR 6 CS pipes offer exceptional strength and durability due to their high-quality construction. The carbon steel grade used in these pipes is designed to withstand extreme temperatures and pressure .In addition to the marking specified in Specification A 999/A 999M, the marking should have the length, an additional symbol -S-, if ASTM A333 Grade 6 Carbon Steel Seamless Pipes conforms to any of the Supplementary Requirements S1 to S6, the schedule number of the pipe is ordered to a schedule number viz. SCH 5,10,20,30,40,60,80,100,120,140,160,XS, XXS, STD, and the .

astm a333 spec sheet

astm a333 seamless pipe

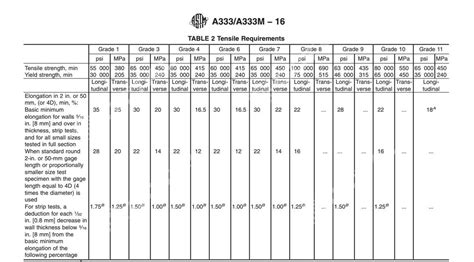

E23 Test Methods for Notched Bar Impact Testing of Me- tallie Materials El 65/E 165M Practice for Liquid Penetrant Examination for . Grade I Grade 3 A333/A333M - 18 TABLE 2 Tensile Requirements Grade 8 psi MPa 100000 690 75000 515 Longi. Trans. tudnal verse 22 1.250 Grade 9 psi Mpa 63 435 46000 315Table 6 of ASTM A333 specifies a test temperature reduction of 4°C below the specified test temperature for Grade 6 because the material thickness is nominally 7mm. The impact test specimen width is only 5mm (71% of the material thickness) and Table 6 specifies a temperature reduction of 11°C.

Savoy Piping Inc is highly Acclaimed Manufacturer & Stockist of Carbon Steel A333 Grade 6 Seamless Pipe and Industrial Carbon Steel Pipes in All Grades of Carbon Steel like ASTM A333 Grade 6 Low temperature Pipe. Fast Delivery Guaranteed for . Hydrostatic Test Impact Test One notched bar impact test, consisting of breaking three specimens .

astm a333 gr6 pipe

Typically material test reports for SA-333 Grade 6 state that it is normalized and tempered, but confirm this from supplier. . Shell piping specs for low temp using A333 Gr 6 requires impact testing at the specified lower design temp for temps ranging from 0degC to -50degC. Upvote 0 Downvote. Status The Charpy V-notch impact test is commonly used to measure the toughness of steel. A333 Gr 6 has a minimum average impact energy value of 20 ft-lbf (27 J) at -50°F (-45°C). This means that even at extremely low temperatures, A333 Gr 6 can withstand sudden impacts without breaking, ensuring the safety and reliability of the application. By providing these details, you can ensure that the vendor supplies the appropriate ASTM A333 Gr 6 pipes that meet your specific needs. Chemical Composition of ASTM A333-6 Material. ASTM A333 Gr 6 pipe material .

A333 Grade 6 Steel Pipe can withstand impact toughness at -45C (-50F) , A333 Grade 6 seamless pipes Commonly used in applications where pressure piping is exposed directly to cold environments below freezing point. ASTM A333 Gr 6 .

Impact Test For Pipe A333 Gr. 6 - posted in Industrial Professionals: Dear AllI need to know way of calculation temperature reduction when we use sub size specimen.My problem:I have tested an A333 Gr.6 (4" pipe-6.3 mm thickness). Labratoary used a sub size specimen (55*5*10). and they tested it in -48c. test temperature of A 333 Gr.6 is -45C .Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse effect on low-temperature impact properties. A333 pipe is furnished to Grades 3 and 1/6. For Additional Grades, please call +1 (800) 325-1584

specimens may be taken from a test plate of the same material as the pipe, the test plate being attached to the end of the pipe and welded as a prolongation of the pipe longitudinal seam. TABLE 1 Chemical Requirements Element Composition, % Grade 1A Grade 3 Grade 4 Grade 6A Grade 7 Grade 8 Grade 9 Grade 10 Grade 11Charpy Impact Testing: Charpy impact testing assesses the pipes’ resistance to low-temperature brittleness by subjecting them to impact loads at low temperatures. This test ensures that the pipes maintain their toughness in extreme cold conditions. . Explanation: ASTM A333 Grade 6 steel requires a minimum impact energy of 27 J (19.9 ft-lbf . Impact test is a prescribed mandatory requirement for ASTM A333 Gr.6. Impact Test Value for ASTM A333 Grade 6 Pipe. Speciman Size, mm. Minimum Average Impact Value for Three Specimens. Minimum Impact value for One Specimen. 10 by 10. 13 ft/lbf. 18 J. 10 ft/lbf. 14 J. 10 by 7.5. 10 ft/lbf. 14 J: 8 ft/lbf. 11 J. 10 by 6.75. 9 ft/lbf. 12 J. 7 ft .

ASTM A333 GR.6 Pipes Charpy V-Notch Impact Test. Toughness, or ductility, is the ability of a material to resist impact, to withstand repeated reversals of stress, or to absorb energy when stressed beyond the elastic limit. Steel is normally considered to be a ductile material, however, it may shatter just as glass at certain low temperatures. .

ASTM A333 Grade 6 is a seamless and welded carbon steel pipe designed to withstand temperatures as low as -45°C, with a minimum tensile strength of 415 MPa and. . Impact test. Hydrostatic pressure or non-destructive electrical test. .E 23 Test Methods for Notched Bar Impact Testing of Metallic Materials 3. Ordering Information 3.1 Orders for material under this specification should . Grade 1A Grade 3 Grade 4 Grade 6A Grade 7 Grade 8 Grade 9 Grade 10 Grade 11 Carbon, max .Description A333 Grade 6 Pipes & Tubes . A333 Grade 6 Pipes is the standard specification for seamless and welded steel pipe for application in low temperature services and other applications with the required notch toughness. ASTM A333 Grade 6 pipe is common use material for low temperature services in above -45℃, with yield strength minimum at 240 Mpa, and tensile .

The ASTM A333 Grade 6 low alloy steel seamless pipes are intended for low temperature services with minimum design temperature -45°C [-50°F] requiring notch toughness. . Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test. Surface treatment: Oil-dip, Varnish .

steroid drops allergy test

steroid eye drops drug test

Aqui você encontra as mulheres loiras acompanhantes ribeir.

a333 gr.6 impact test|astm a333 gr6 pipe